The Single Strategy To Use For Laser Cutter

When it comes to contemporary manufacturing, the precision and performance of laser slicing know-how are genuinely sport-changing. Laser chopping devices have revolutionized industries by providing a means of reducing products with unparalleled accuracy. If you’ve at any time marveled in the intricate designs on steel or wondered how elaborate designs are manufactured so seamlessly, it’s typically the function of the industrial laser cutting device.

Enable’s start with the fundamentals: a laser cutter is a Device that takes advantage of a laser beam to cut products. This beam is amazingly concentrated and generates large temperatures to soften or vaporize the material, generating specific cuts. As opposed to regular techniques, which could use mechanical blades, a laser cutter provides a degree of precision that is sort of unmatched. Envision looking to carve a fragile pattern by using a hammer—Evidently, a laser cutter is a lot far more refined!

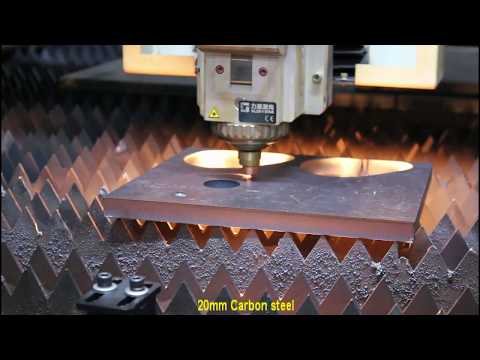

Industrial laser chopping requires this engineering to the subsequent amount, providing answers for big-scale functions. These equipment are built to handle hefty components and significant output volumes, ensuring that even one of the most demanding jobs are done with high efficiency. Think of it as the difference between using a precision knife for fragile paper crafts and a strong observed for chopping through thick wood.

The 10-Minute Rule for Industrial Laser Cutting

On earth of CNC laser reducing, the “CNC” means Computer Numerical Command. This engineering allows for automatic and hugely precise cuts by following electronic patterns. In the event you’ve at any time applied a computer to draw after which you can witnessed that drawing come to life, CNC laser slicing operates in a similar way, translating digital styles into Actual physical cuts. It’s like getting a virtual designer Along with the precision of a laser.

On earth of CNC laser reducing, the “CNC” means Computer Numerical Command. This engineering allows for automatic and hugely precise cuts by following electronic patterns. In the event you’ve at any time applied a computer to draw after which you can witnessed that drawing come to life, CNC laser slicing operates in a similar way, translating digital styles into Actual physical cuts. It’s like getting a virtual designer Along with the precision of a laser.The Single Strategy To Use For Cnc Laser Cutting

Precision laser slicing is just not almost producing cuts; it’s about producing them proper every single time. The laser can be altered to accomplish diverse depths and widths, making certain that every Slash is precisely the place it has to be. This can be essential for purposes wherever even a slight deviation may lead to substantial issues. Imagine it like a surgeon’s scalpel, exactly where precision is not merely critical but Completely significant.

Precision laser slicing is just not almost producing cuts; it’s about producing them proper every single time. The laser can be altered to accomplish diverse depths and widths, making certain that every Slash is precisely the place it has to be. This can be essential for purposes wherever even a slight deviation may lead to substantial issues. Imagine it like a surgeon’s scalpel, exactly where precision is not merely critical but Completely significant.Laser reducing machines comes in various varieties, Every personalized to particular requires. No matter whether you need a smaller desktop model for interest projects or an enormous industrial equipment for factory use, there’s a laser chopping Answer to choose from for you personally. These devices vary in electricity, velocity, and capabilities, so it’s essential to choose the appropriate a person to your individual application.

Sheet steel laser cutters absolutely are a Particular group of laser chopping machines created especially for reducing metal sheets. They can be greatly Employed in industries ranging from automotive to aerospace due to their capacity to tackle metal with precision and speed. Photo a sheet of metallic similar to a blank canvas, and the laser cutter because the artist who results in elaborate and delightful styles with extraordinary accuracy.

Laser reducing companies are A further vital aspect of this technologies. Not Every person wants to take a position in their very own laser slicing equipment, particularly when they only will need occasional cuts or deficiency the Place for these types of machines. Lots of companies give laser chopping expert services in which you can send out your types and also have them Lower with higher precision. It’s like outsourcing your artwork to a skilled professional.

Laser chopping devices combine a variety of elements to deliver the specified effects. With the laser supply for the cutting mattress, along with the Management computer software, each part of the procedure performs collectively to make sure a flawless Procedure. It’s a tad like a symphony orchestra, where by Every single musician has a particular job, and only by Doing work with each other do they make a harmonious efficiency.

When it comes to laser slicing engineering, the evolution has been quick and impressive. To begin with utilized generally for cutting metals, these devices go here now handle a wide array of materials which includes plastics, Wooden, and also fabrics. This flexibility tends to make laser reducing technological know-how a useful Resource in countless industries. Think about aquiring a Swiss Army knife that will cope with almost any content—This read on is often what contemporary laser reducing know-how offers.

The accuracy of laser reducing devices is really extraordinary. They are able to Lower elements to in just microns of the intended layout, guaranteeing that even quite possibly the most intricate details are preserved. This level of precision is particularly beneficial in see the full story industries in which actual measurements are critical. Think about it since the distinction between a customized match and off-the-rack garments—the in shape is simply best whenever.

The 2-Minute Rule for Cnc Laser Cutting

One more benefit of laser reducing know-how is its efficiency. As opposed to regular cutting approaches Which may need a number of ways or resources, laser slicing normally completes the job in one go. This not simply speeds up creation but in addition reduces materials waste. It’s like using a superior-speed teach that will get you on your desired destination quickly and effectively with no unneeded stops.From the context of industrial purposes, the robustness of laser chopping equipment is crucial. These machines are built to endure the demands of steady operation, frequently working 24/7 in large-volume settings. Their durability makes certain steady general performance and reliability, which can be essential for keeping creation schedules. It’s like getting a large-duty truck that reliably delivers goods working day after working day.

One of the remarkable components of laser chopping is its capacity to generate thoroughly clean and precise edges. This cuts down the necessity for submit-processing, like sanding or ending, which can be time-consuming and costly. The result is usually a clean, finished product That always calls for minimum additional do the job. Think about finishing a craft job without having glue spills or rough edges—it’s that clean!